A typical large continuous processing manufacturing facility has between 1,000 and 20,000 critical motors installed in the plant. The facility will typically purchase or repair between 10 and 100 critical motors each month. The cost of repair or replacement motors, the labor, and the down time associated with each repair can represent a significant portion of a plant’s maintenance budget. In order to control these costs, a motor management program is essential.

Typically management of each of the plant’s hundreds or thousands of motors will first be attempted with the existing computerized maintenance management system (CMMS). In the plant, it soon becomes obvious that the plant CMMS is not capable of managing reliability information on re-buildable assets that migrate.

Next plants often try to accomplish motor tracking using a homemade database in Access or Excel. This approach is usually very difficult to keep current and fails to be usable by more than one person. The TANGO equipment lifecycle management software, produced by 24/7 Systems, is designed specifically to accomplish the management of re-buildable assets. This paper discusses the use of TANGO as a web-hosted motor management program.

From the plants perspective, motor management is performed to achieve two objectives:

- Eliminate unexpected motor failures

- Extend the life of motors between overhauls

Integrating motor reliability and condition information is critical to the above objectives but the information comes from multiple subcontractor, vendors, and in-plant sources. So how can the plant with its limited manpower and resources realize the potential advantages of motor management?

Some plants have found that they can utilize their motor repair vendors and new motor suppliers to do most of the work of motor management for them. The TANGO equipment lifecycle management software provides the tools for integrating the diverse reliability information from multiple sources and allowing it to be viewed and analyzed in one system. TANGO system is web-hosted and allows the strength of plant/subcontractor partnership to be utilized.

The advantages to the plant of having their own overhaul shop(s) assist them with managing motors with a web-based application include:

Reduced data entry

The vendor is providing purchase and repair documentation in the normal course of business, so entering it into a web-hosted database relieves the plant of reentering data or trying to track down hard copies scattered among various file cabinets.

Consistency and Availability of Information

Often the various plant functional areas, units, or stations create their own tracking applications using Access or Excel. These independent sources rarely use the same nomenclature that allows other plant users to integrate the information, and the files may not be accessible by all interested parties. With a single web-hosted database a common nomenclature can be enforced, and information is available to any authorized manager or employee with Internet access.

Removes the plant CMMS limitations

Often the plants CMMS system does not have the capability or user interface needed for storing and retrieving asset life cycle or condition information.

1. Eliminate Unexpected Failures

The plants first requirement for motor management is the elimination of in-service motor failures. Predictive Maintenance (PdM) technologies provide information about the current status of motor health, and motor vendors have become key suppliers of PdM services. These technologies include:

- Vibration Analysis

- Infrared Thermography

- Motor Circuit Evaluation

- Current Signature

- Bearing/Winding Temperature

- Ultrasonic Inspection

From the trending and analysis of these tests, a set of standards can be established which when exceeded cause the motor to be removed for repair and prevent failure in service. The difficulty in tracking a motor’s condition occurs because multiple condition technologies must be applied and there are no effective standards in place to facilitate integration of reporting between different vendor’s software. Also, the traditional deliverable from PdM service suppliers has been hard copy or emailed reports to a few individuals at the plant; other employees or managers who could benefit from the ‘warning’ information often never receive it.

2. Extend Motor Life

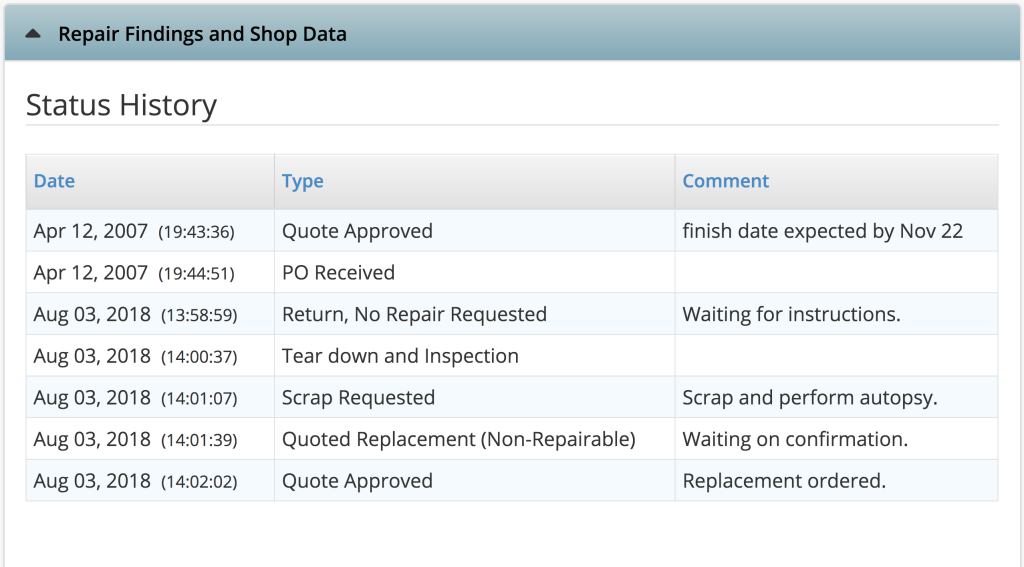

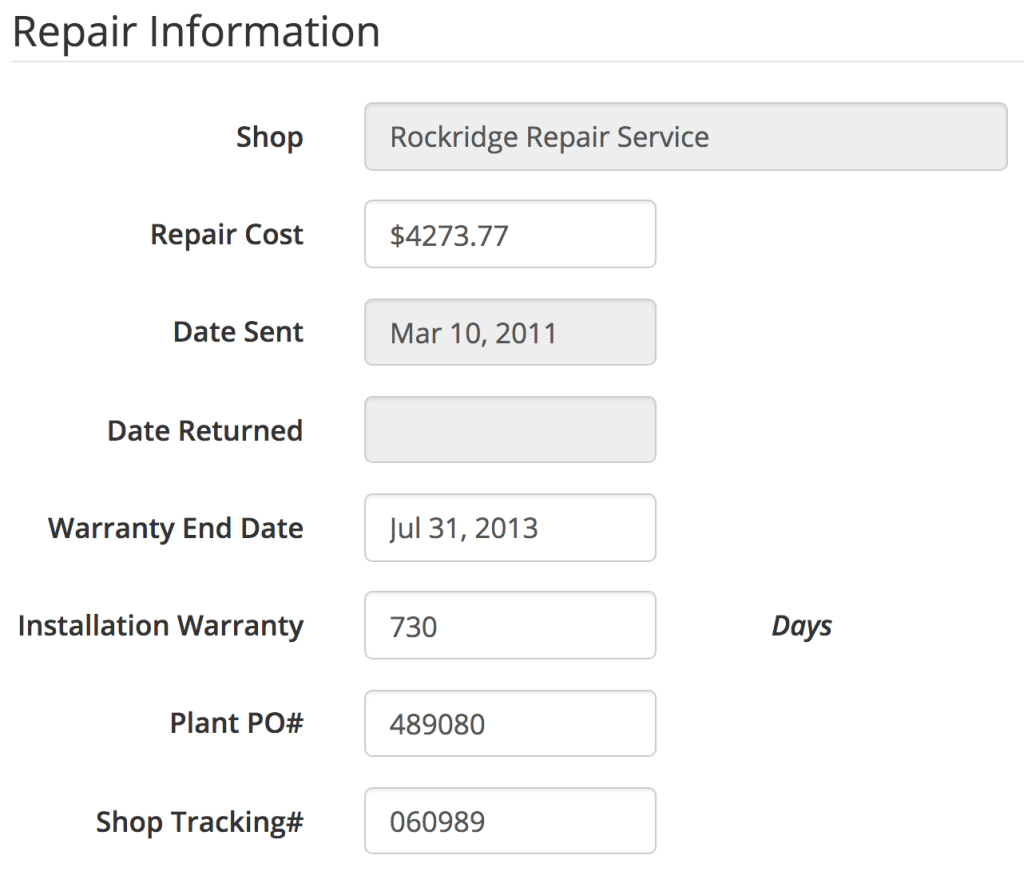

When a failed motor is sent to the motor repair shop, the first step is disassembly and inspection. At this point, the shop knows the basic design and failure information about a motor. Once a repair has been approved and performed by the shop, the shop also knows the cost of repair and warranty period.

- Design Information

Design information on motors needed by the plant goes beyond just the nameplate data. Information such as a bearing currently installed, number of bars and slots, insulation class, and full load current is extremely helpful for plant condition analysis and testing, purchasing, and routine maintenance. - Root Cause of Failure

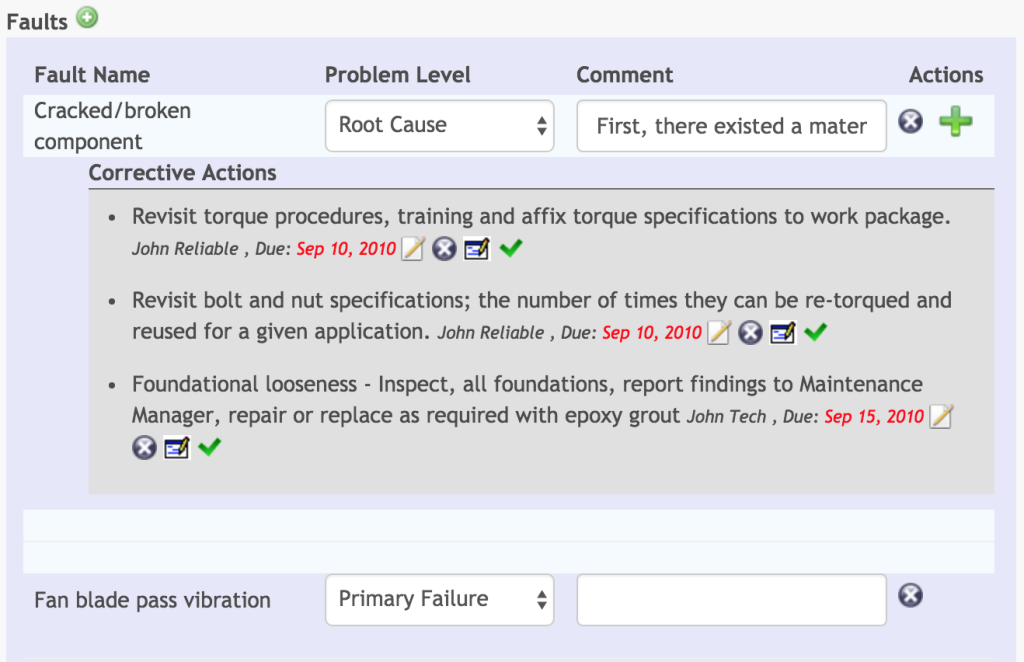

Typically the plant will see the motor’s failure as why it stopped functioning, which is either “winding failure” or “bearing failure”. This level of information is not helpful in assisting the plant in understanding how to make the motor live longer. The shop can usually determine the root cause of failure such as:

• Over greasing

• Dirty cooling passages

• Overload

• Power quality

• Inadequate lubrication

• Lighting strike

• Internal moisture

• Excessive starts

• Wrong lubricant

Once the plant knows root causes of failures, action can be taken to eliminate the root cause and obtain longer motor life. - Date Received and Shipped

These dates will allow the calculation of Mean Time to Repair and Mean Time Between Repairs. - Cost of Repair

Upon disassembly and inspection, the plant may decide to overhaul the motor or to scrap it and purchase a new motor. In either case, the cost of the failure needs to be stored with the failure information. - Warranty

Motor warranty is a special consideration of motor management. Overhauled motors often have 1 or 2 year warranties and new motors 1 to 5 year warranties. Many plants do not pursue warranty claims because the system required to easily warn them of a potential warranty claim does not exist. Often the savings obtained from warranty tracking will more than pay for the complete motor management package.

Typically a motor repair shop returns paper or email documentation to the plant detailing repairs, post repair testing, new design information, and cost. Quite often this report is hard to retrieve within a few weeks of receipt by the plant. Whether the hard copy was placed in an office file cabinet, or email was archived in a computer folder along with hundreds like it, it becomes very difficult to retrieve and use for meaningful analysis.

From the motor repair shop perspective, the biggest challenge for most shop’s operations is capturing good root cause of failure information. Joe Longo, President of Longo Electrical Mechanical in Wharton, NJ, leads a large progressive apparatus repair facility and believes that root cause of failure information is not being analyzed well across the repair industry. “Just telling a customer they had a winding failure is not sufficient”, according to Longo. Instead, they need to know if the winding failure was caused by mechanical, environmental, or electrical sources. “Finally we have a tool that prompts us to capture root information consistently. Before Tango lots of people talked about reliability but no one knew how to produce the information for our customers.”

Solution: TANGO™ Motor Management Web Service

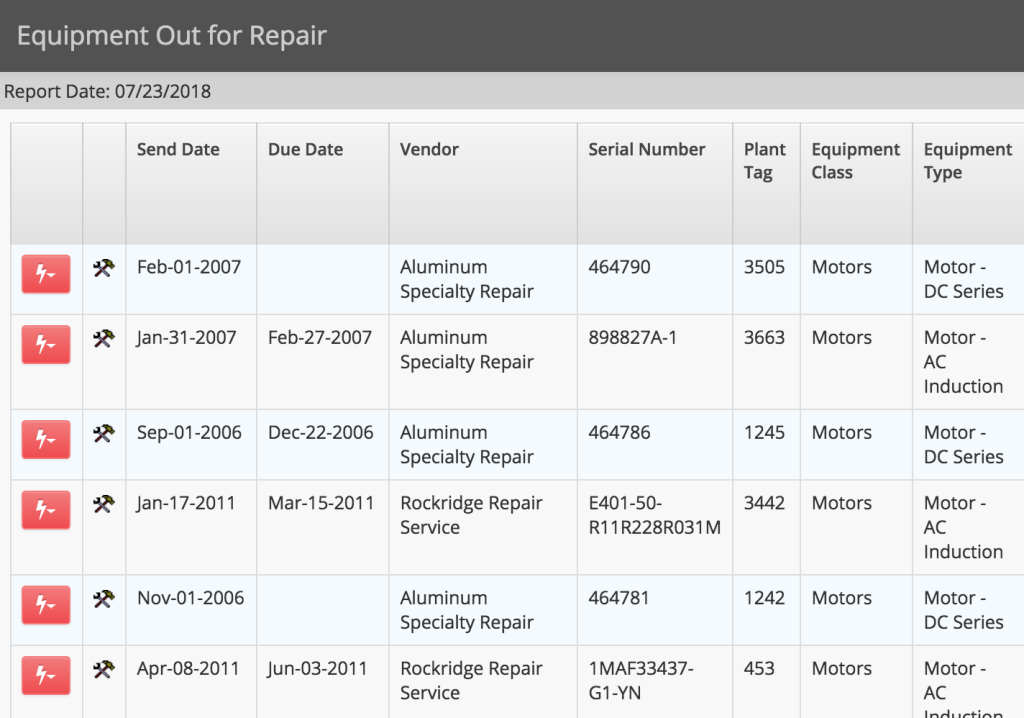

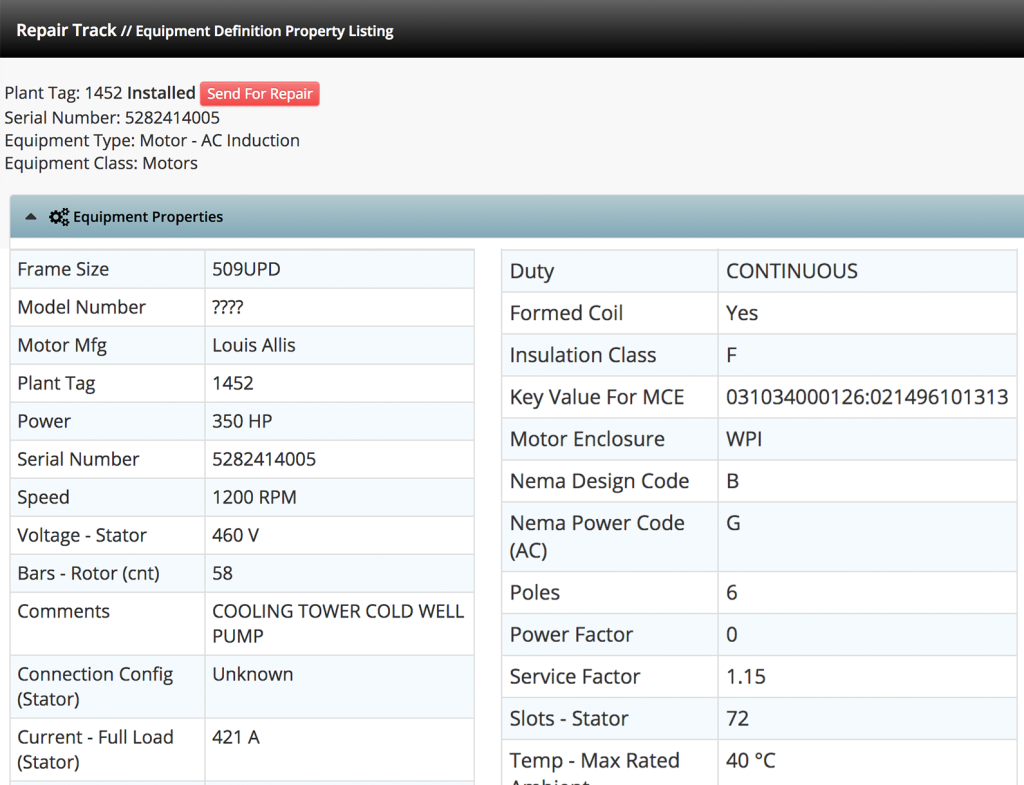

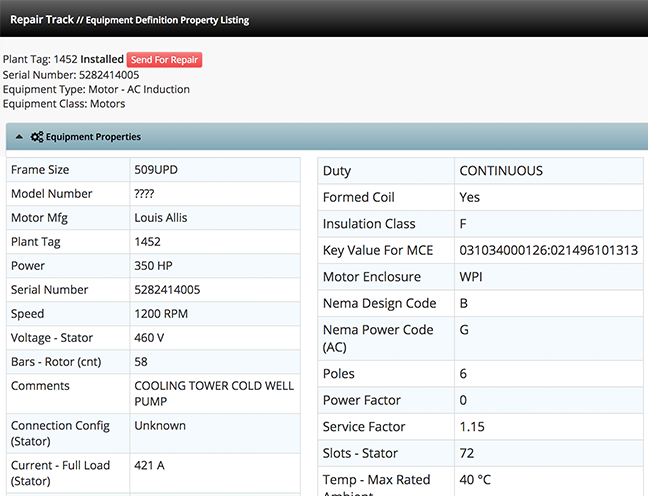

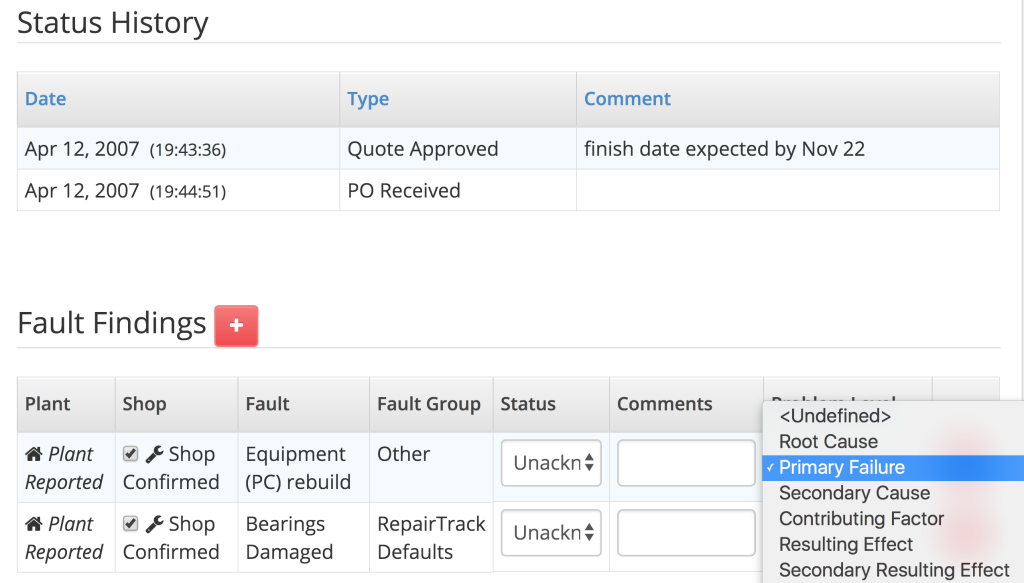

Using the Tango™ web based motor management approach; the repair shop enters the motor ID, design information, failure analysis, repair, and cost information into a web form. In addition the repair details and photos can be attached. This information is then automatically entered into the web database and creates a life cycle repair history for the specific machine. In addition to the history for each machine, the database can produce information on Mean Time Between Repairs, root causes of failure, and cost of repair. This information could be further sorted or analyzed by size, vendor, repair vendor, voltage, type of motor, cost by year, etc.

Repair Tracker™

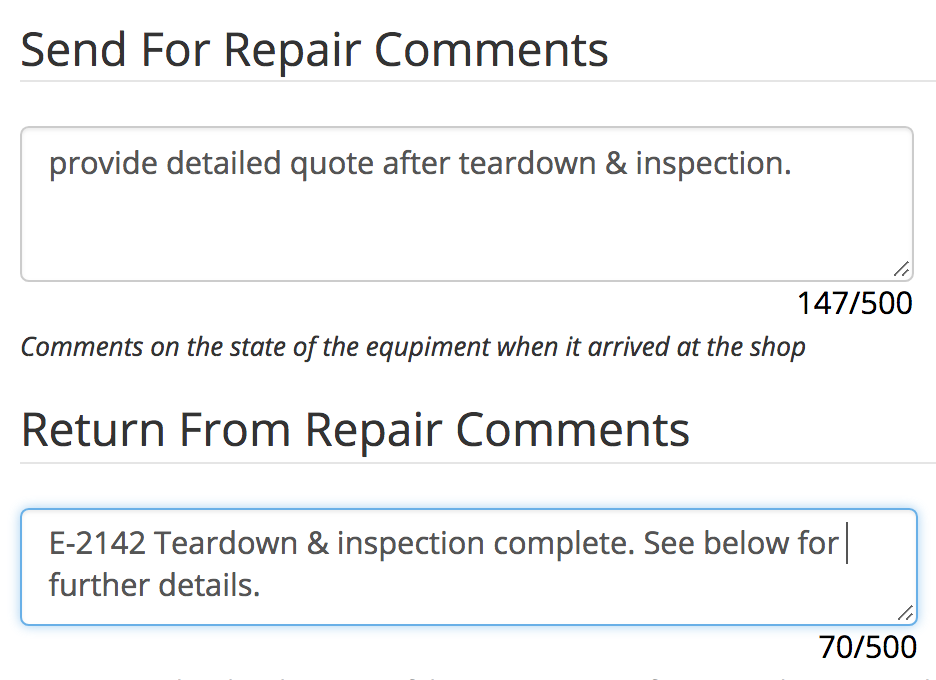

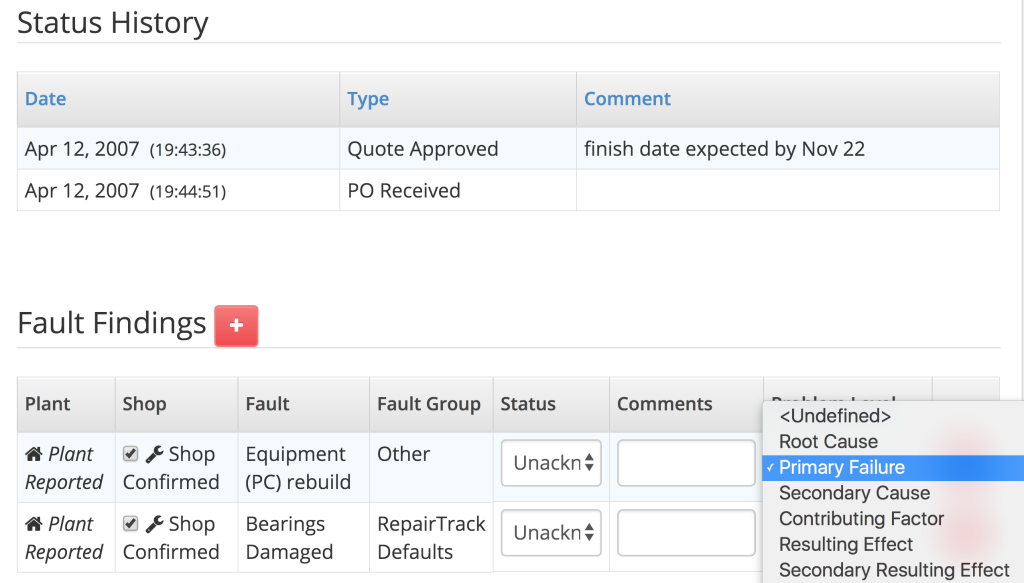

Repair Tracker™ provides the ability for repair shops to enter motor design, failure, repair and repair status information.

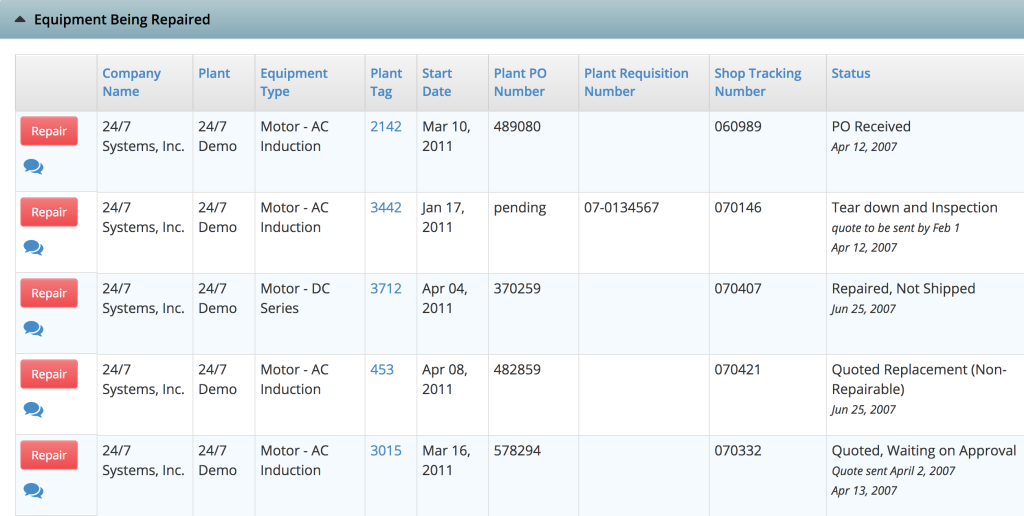

Figure 4 shows the RepairTracker start page. This view shows all of the motors in the shop for repair and the status of repair for each motor.

For equipment being repaired, the view option allows the shop to enter the failure reasons, photographs, documents and warranty information. The customer may view this information in a read-only view.

Conclusion

Effective motor management requires lifecycle tracking to capture the design, condition status, repair, and failure root cause information that comes from a wide variety of sources. A web-based motor management system allows a motor repair vendor to become a working partner to capture this information for a plant, without having to get involved with the plant’s IT firewall issues.

Web-based motor management systems also facilitates broad communication of critical reliability issues to interested plant users without additional manpower burden to the plant. The motor vendor becomes an essential partner for the plant’s motor management effort. TANGO Equipment Life Cycle Management, produced by 24/7 Systems, is the enabling technology that allows motor repair vendors to provide a web-based motor management service for large industrial accounts.